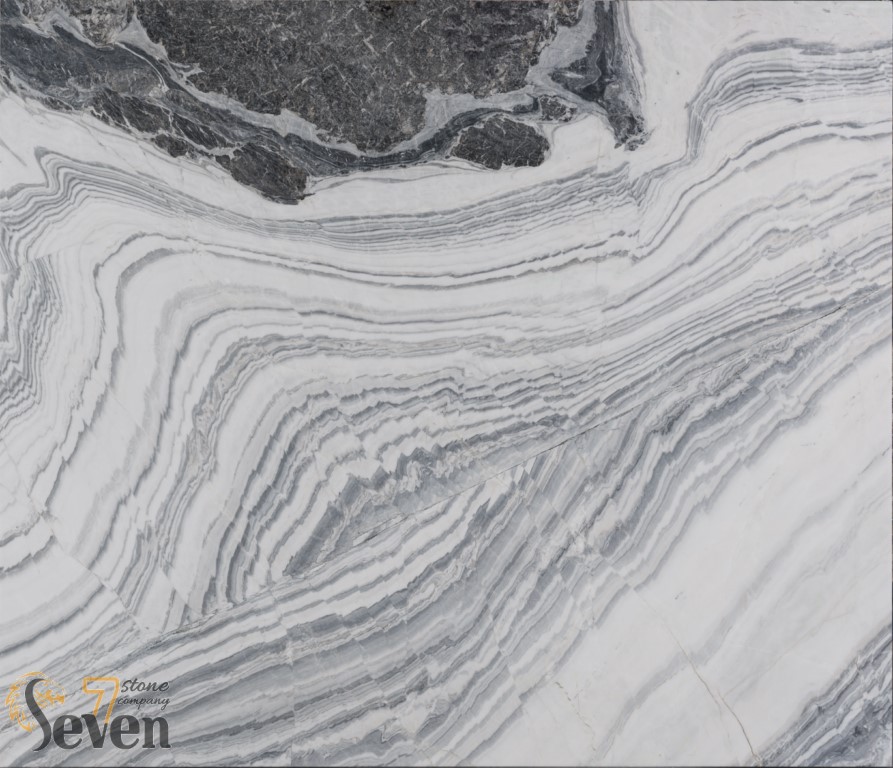

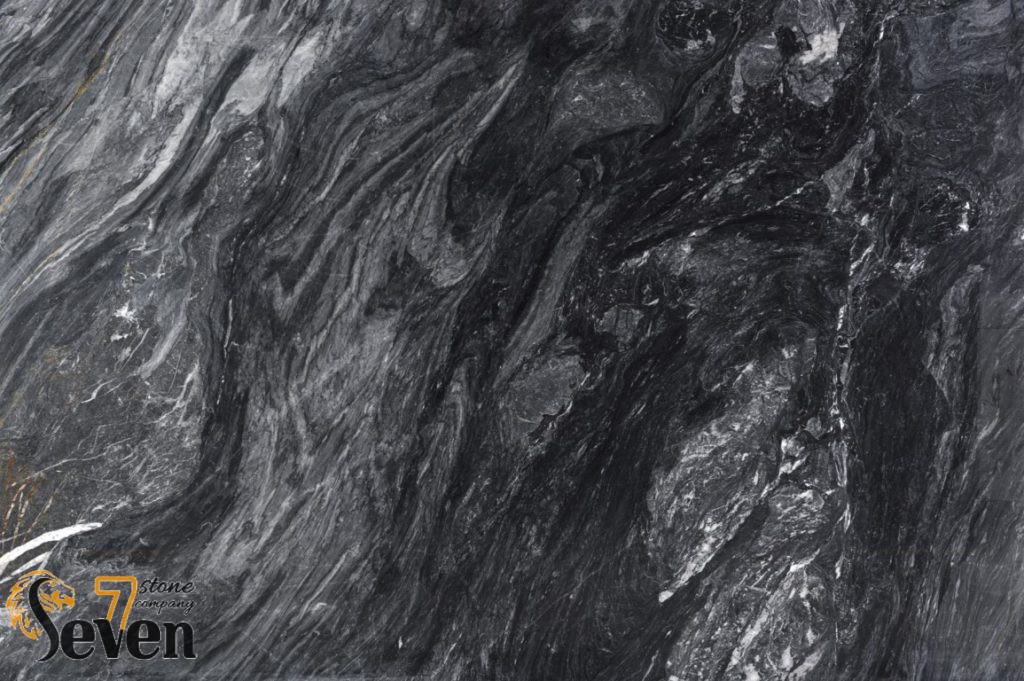

Crystalline marble is one of the most high-quality and durable building stones. In our country, there are many porcelain or crystal mines in different regions of the country. Among the most famous crystal stones of the country, we can mention Azna porcelain stone, Aliguderz, Niyriz, Qorveh, etc. But one of the famous crystal stones in the world is Marmara White Marble of Turkey, which has a very special and unique appearance and very suitable physical characteristics, and mainly Turkish Marmara crystal stone is produced and processed in the form of slabs. Marmara stone of Turkey has a white background color and gray lines and shawls can be seen on its surface.

Crystal stone or porcelain stone is one of the limestone or dolomite stones that undergo changes in their structure and recrystallize due to exposure to high pressure and temperature conditions. For this reason, they are classified as metamorphic rocks. In fact, it can be said that Chinese stones are in the category of marble stones. Marble stones can be very different by having different chemical compositions and the degree of transformation.

It is very common to use Turkish Marmara crystal slabs in spaces and places that are exposed to moisture and constant contact with water, such as bathrooms, luxury and master bathrooms, washrooms, and swimming pools.

Characteristics of Turkish Marmara crystal slabs

- Very high density

- Suitable subduction

- Very high strength

- Good abrasion resistance

- High compressive strength

- Very low water absorption

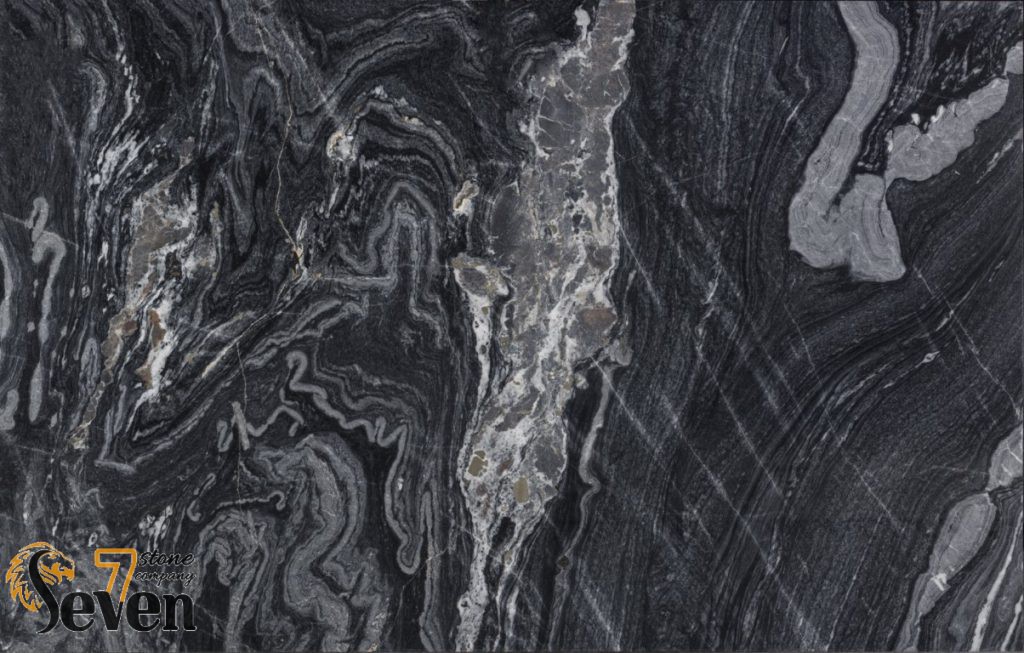

- The ability to create very beautiful book match and form match slab frames

- Resistant to moisture, cold and heat

- Reasonable price compared to competitors

Crystal slab stone Turkish Marmara is used in many different cases due to its appearance characteristics and very suitable structural parameters. Marmara stone is one of the most beautiful and special types of porcelain or crystal stone, whose most important features are its exemplary strength and the ability to create bookmatch and formmatch frames, which has led to a significant increase in the sale of this stone.

For slab processing, export coupes with large dimensions (single coupe) are needed and the processing steps must be done carefully so that the stones do not break. The dimensions of the slab sheet sometimes reach 3 meters in length and 2 meters in width. The size of the slab sheet also depends on the size of the slab and the dimensions of the stone cube purchased from the quarry. In addition to the large size of the raw cup, the health and absence of fractures in the cup causes the extraction and processing of good and large stones.

Mainly Turkish Marmara stone is processed in factories that are equipped with quality and up-to-date machines. This stone is produced and supplied both in the form of slabs and tiles. But its production with the slab method is more cost-effective and in terms of processing it has a much higher quality than tile.

Turkish Marmara crystal stone has very high strength and its density is also very suitable. Therefore, the proper absorption and polished and shiny surface of this stone is not far from the expectation. The very low water absorption of Marmara stone has caused this stone to be used in many spaces that are exposed to moisture and direct contact with water, and moisture does not affect the health of this stone.

Structural analysis of Marmara crystal rock

| The desired amount | Water absorption | Special Weight | porosity | pushing resistance | Abrasion Resistance |

| MIN | 0/03 | 1/80 | petty | 600 | 2/20 |

| MAX | 1/50 | 2/80 | 2/50 | 2200 | 6 |

| Marmara crystal stone | 0/10 | 2/74 | 0/20 | 910 | 3 |

Advantages of buying and using stone slabs

The processing and preparation of stone in the form of slabs has many advantages over the old methods, and apart from the beauty and eye-catchingness of the stone, the strength and lifespan of the stone also increases significantly. In this processing method, high-quality and modern devices are used for cutting and calibrating, as well as sub and polishing the stone, and due to the epoxy work and the installation of a net behind the slab sheet, the possibility of breaking and crushing the stone is minimized. In general, the advantages of buying stone slabs are:

- More strength

- stunning beauty

- Ease of transportation and loading

- Ease of stone selection

- The ability to create book match and form match pages

- Lighting capability

For the processing of slabs, export coupes with large dimensions (single coupes) are needed, and the processing steps must be done carefully so that the stones do not break. The dimensions of the slab sheet sometimes reach 3 meters in length and 2 meters in width. The size of the slab sheet also depends on the size of the slab and the dimensions of the stone cube purchased from the quarry. In addition to the large size of the raw cup, the health and absence of fractures in the cup causes the extraction and processing of good and large stones.

Uses of Turkish Marmara crystal slabs

- The interior of the building

- Paving the floor of the hall and reception

- Paving the floor of the lobby and entrance halls

- The internal walls of the building

- The wall of the fireplace

- Elevator frame and edge

- The space behind the TV (TV Wall)

- Business centers and luxury stores

- Counters of public and commercial centers

- Luxury bathrooms and master bathrooms

Due to the economic problems and currency fluctuations, as well as the ban on the import of many goods to the country, the price of imported stones experienced a significant increase. But the need for these types of stones and their use in luxurious and luxurious designs and spaces has caused the demand to buy imported stones to be maintained as in the past. The cases of using foreign and imported stone slabs are very diverse and they are mainly used in the interior of the building.

Factors affecting the price of Marmara stone slabs

- The size and shape of the stone cup

- The type and nature of the stone

- The costs of extracting and buying coop

- Cutting and processing

- Sort or grading of stone

- Cleanliness and minimum amount of streaks on the surface of the stone

- The ability to create book match and form match frames

- Shipping costs