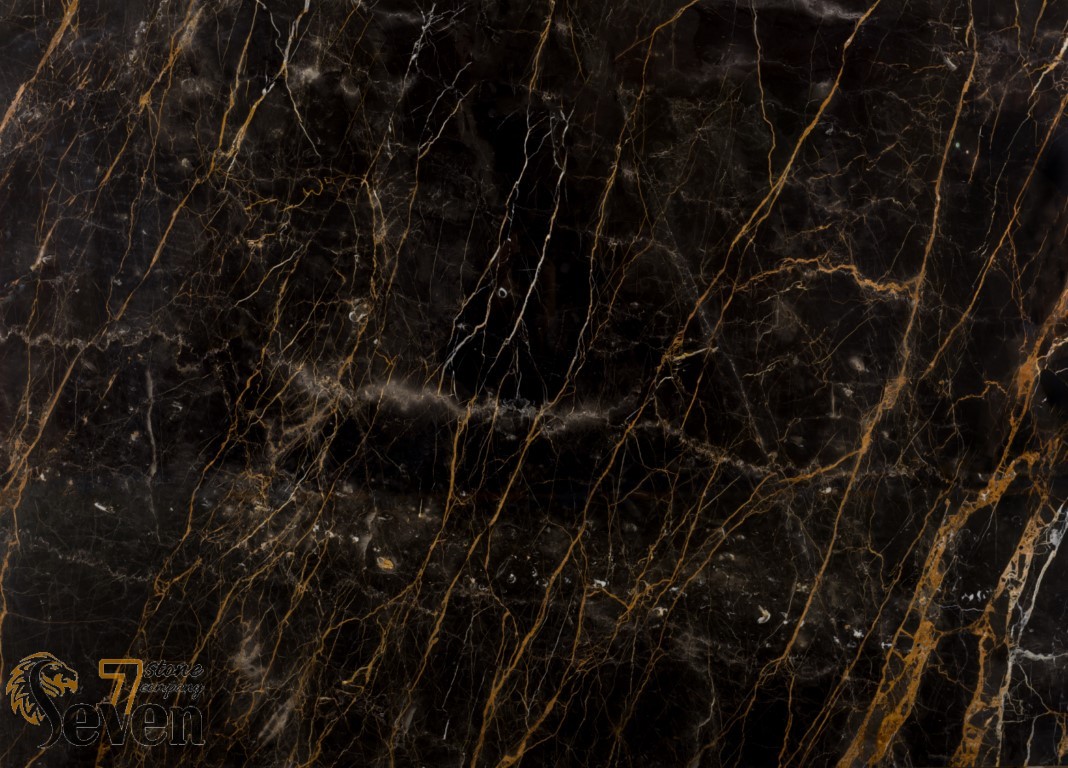

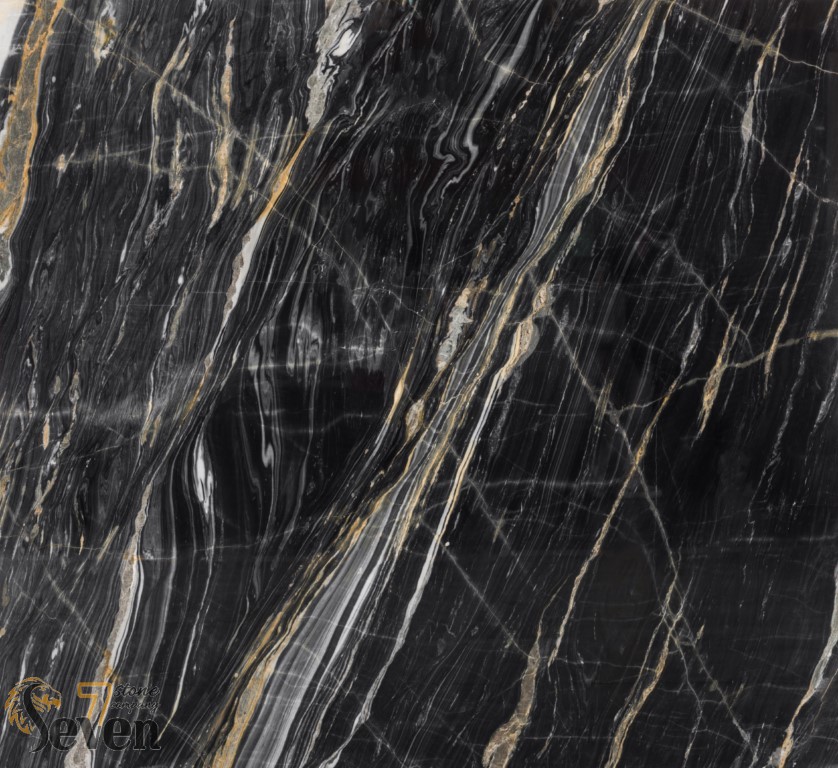

Golden Galaxy marble has a black background and very beautiful white and golden lines can be seen on its surface. The quarry for extracting this stone is located in Central Province. This stone is extracted in different grades and quality grades and processed into slabs and tiles, which have specific parameters to determine its quality grade. In terms of appearance, the higher the number of golden veins, the higher the quality and the higher the price. Also, the darker and blacker the background color of the stone is, the more premium the stone is and the higher its quality.

Golden Galaxy marble, having a beautiful and eye-catching appearance, as soon as it enters the country’s market, has taken a very suitable position. Also, due to the very reasonable price, this stone has been well received in the global market and Golden Black stone has a significant share in exports.

Golden Galaxy black and gold features:

- Relatively high density

- Suitable subduction

- Polished and shiny surface

- High abrasion resistance

- High compressive strength

- Relatively low water absorption

- Unique appearance

- Very reasonable price

- And …

This stone is somewhat rare due to the limitation in the extraction and supply of copper, and also because of the major export and the high demand for this product, it is processed and supplied in a specific and limited manner. The use of Golden Galaxy stone along with lighter stones has created a very beautiful and eye-catching combination that gives glory and a special effect to the space and building. In many interior luxury designs of this stone on the floor and walls of the building, next to white, cream and generally light stones, it creates a very beautiful combination.

Structural analysis of Golden Galaxy Golden Stone:

| The desired amount | Water absorption | Special Weight | porosity | pushing resistance | Abrasion Resistance |

| MIN | ۰/۰۳ | ۱/۸۰ | petty | ۶۰۰ | ۲/۲۰ |

| MAX | ۱/۵۰ | ۲/۸۰ | ۲/۵۰ | ۲۲۰۰ | ۶ |

| Golden Galaxy marble | ۰٫۶۲ | ۲/۵۸ | ۰/۷۸ | ۱۲۶۰ | ۳ |

Today, the use of Golden Galaxy black and gold slabs in the design of the interior of the building is much more widespread than in the past. Stones with a black background and white and gold streaks are often used as slabs in various spaces such as cabinets, lobby, reception, etc. Mainly, the golden and white streaks on the surface of these types of stones have the ability to create book match and form match frames. The black stones that are processed in the form of slabs are mostly marble, crystal (china) and granite.

Advantages of buying stone slabs:

The processing and preparation of stone in the form of slabs has many advantages over the old methods, and apart from the beauty and eye-catchingness of the stone, the strength and lifespan of the stone also increases significantly. In this processing method, high-quality and modern devices are used for cutting and calibrating, as well as subbing and polishing the stone, and due to the epoxy work and the installation of a net behind the slab sheet, the possibility of breaking and crushing the stone is minimized. In general, the advantages of buying stone slabs are:

- More strength

- stunning beauty

- Higher processing quality

- Ease of transportation and loading

- Ease of stone selection

- The ability to create book match and form match pages

- Lighting capability (in marble or onyx stones)

- And …

In the production of Golden Galaxy black and gold marble slabs, if you use the right equipment and perform the sub operation correctly, it will bring a very high quality and stunning beauty.

Uses of Golden Galaxy marble slabs:

One of the biggest features and advantages of the golden black slab stone of Golden Galaxy is the shiny and polished surface of the stone. In the production of slabs of these stones, if the appropriate equipment is used and the sub operation is carried out correctly, it will bring a very high quality and stunning beauty. The mentioned positive features, along with the very reasonable price of internal stones, have caused these stones to become a serious competitor for foreign stones, one of the suitable options for use in luxury buildings, in the focus of designers and builders. Among the most important and major uses of all kinds of black and golden stones in the form of slabs, the following can be mentioned:

- The interior of the building

- Paving the floor of the hall, reception and rooms

- The interior walls of the building

- Margins and sides

- Hotels, shops and luxury business centers

- Stairway stone and under the stairs

- Stair treads and walls

- The entrance lobby of the building

- Edges and frame of the elevator

- Cabinets and kitchen space

- Luxury and master bathrooms

- Luxury bathroom

- The counter of public centers

- And …

Currently, slab stones are processed from large and export coops. The price of this stone has undergone changes according to market fluctuations. But in the slab processing method, according to the type of cutting and sub quality, the prices are higher than the tile method. Considering the increase in the price of raw copper and other production costs, slab processing is cost-effective. Because it has less waste and using advanced devices, sub, epoxy, UV, etc. operations are performed on it. If the polishers are of good quality and the processing and sub-processing operations are carried out correctly, the polished and shiny surface of Golden Galaxy marble will be more attractive.

Factors affecting the price of Golden Galaxy marble:

- The size and shape of the stone cup

- The type and nature of the stone

- Coup mining and purchase costs

- Cutting and processing

- Sort or classification of stone

- Cleanliness and minimal streaks on the surface of the stone

- Shipping costs

- And …

As mentioned, Golden Galaxy black and gold marble is processed and supplied in the form of tiles and slabs. The dimensions of the processed slabs are different and are determined according to the size of the stone. The approximate dimensions of the slab are 140 to 190 cm in width and 220 to 290 cm in length. In tile processing, stones are processed in widths of 40 cm, 60 cm and 70 cm. The thickness of the cut in export varieties is exactly 2 cm, and the thickness for domestic use is between 17 and 18 mm.