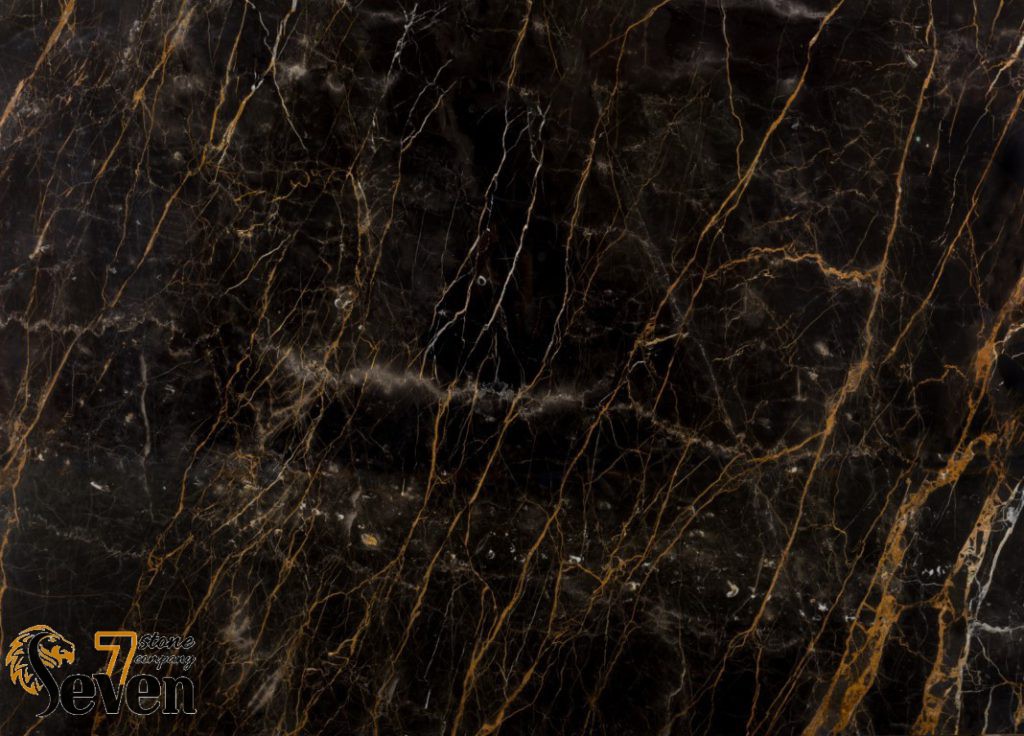

Marble is one of the most widely used and diverse building stones that exist in different designs and colors, as well as in different qualities and materials. One of the most special stones from the marble family is black marble, of which there are currently several examples. These stones are generally found with black background and colored designs and waves. Black & White marble (Black Ocean Marble) is one of the most high-quality and special black marble stones in the country, which is mainly processed and produced in the form of slabs.

Types of marble

Due to the fact that there are marble mines in different places of the world, these mines are scattered in different cities in Iran. Some of their features, such as design, color, and strength against pressure and wear, are different, and when buying this type of stone, you should pay attention to all these things. Of course, the place where the marble stone is going to be used must also be suitable for this stone.

Black & White marble has a black background color and a wide and thin white streak is mainly seen on its surface. The quarry for extracting this stone is located in the suburbs of Mahalat in the central province. Black & White marble is structurally strong, and its high abrasion resistance and higher price compared to other similar stones, such as Najaf Abad black marble, have made this stone to be placed in the category of quality and luxury stones. In the current stone market of the country, there are various stones with black color theme and white lines, some of which are:

- Najaf Abad marble

- Mako black marble stone

- Lashtar marble stone

- 3D black marble stone

- Golden Galaxy black marble

- Black rose black marble stone

Characteristics of Black & White marble slabs

- Very high density

- Excellent flexibility

- Good abrasion resistance

- High compressive strength

- Very high strength

- Higher price than other similar stones

- Relatively low water absorption and penetration

- The ability to create book match and form match frames

- Unique color and beautiful appearance

The aforementioned positive features, along with the relatively higher price of Black & White marble compared to competitors, have made this stone a serious competitor for foreign stones, one of the suitable options for use in luxury buildings, in the focus of designers and builders. Today, the use of black stones in the interior design of buildings is much more than in the past. Black & White marble, with its beautiful white lines, is used in many different cases such as cabinets, elevators, the space behind the TV, lobby, etc.

Applications of marble stone

The main use of marble stones is the flooring and stairs of residential houses and office buildings, but the huge variety of colors of this type of stone has led to their use in other places, such as covering walls, the surface of cabinets and kitchen counters, elevators, washrooms, etc. have a significant increase.

Advantages and disadvantages of marble

Among the most important advantages of marble stones, we can mention their very high resistance to heat, attracting attention and very impressive beauty, high diversity in design and color, and their high absorbability. As for their disadvantages, things like low pressure resistance, high water absorption, and vulnerability to natural factors and acidic substances can be listed.

Marble slab stone

Marble slabs are one of the most important slab stones that are widely used in the construction industry.

One of the special features of marble slabs is the ease of cutting it in different dimensions. The reason for this feature can be the carbonate property of marble.

Sub-receptibility, the ability to polish these slabs and as a result high reflection of sunlight, as well as a great variety of colors, are other characteristics of marble slabs, which has led to a wide range of their use. So that currently in all parts of a building, it is possible to use such slabs.

Black & White marble is widely used in the design of the interior of the building. This stone is used in building floors, elevator floors, curbs, stairs and under stairs. But the noteworthy point is that it cannot be used on the exterior of the building. Because its resistance to the sun is low.

One of the biggest features and advantages of Black & White stone is the shiny and polished surface of the stone. In the production of slabs, this stone will bring a very high quality and stunning beauty if the appropriate equipment is used and the sub operation is performed correctly.

Special analysis of black & white marble

| The desired amount | Water absorption | Special Weight | porosity | pushing resistance | Abrasion Resistance |

| MIN | 0/03 | 1/80 | petty | 600 | 2/20 |

| MAX | 1/50 | 2/80 | 2/50 | 2200 | 6 |

| Black & White marble stone | 0/38 | 2/63 | 0/7 | 1269 | 3/3 |

This stone is somewhat rare due to the limitation in the extraction and supply of copper, and also because of the major export and the high demand for this product, it is processed and supplied in a specific and limited manner.The use of black & white marble slabs along with lighter stones creates a very beautiful and eye-catching combination that gives glory and a special effect to the space and building. In many luxury interior design of the building, this stone is used on the floor and walls of the building, along with white, cream, gray stones and in general light stones, it creates a very beautiful combination.

Black & White marble slabs, having a beautiful and eye-catching appearance, as soon as they enter the country’s market, have taken a very suitable position. Also, due to the very reasonable price, this stone has been well received in the global market and Black & White marble has a significant share in exports.

Factors affecting the price of black & white stone slabs

- The size and shape of the stone cup

- The type and nature of the stone

- Coup mining and purchase costs

- Cutting and processing

- Sort or classification of stone

- Cleanliness and minimal streaks on the surface of the stone

- Shipping costs

In the book matching operation, which includes two parts (book match) and four parts (formach), the cutting and processing of the stone is done in such a way that the natural lines and veins in the slab stone are placed along each other or in symmetry with each other. That is, like a butterfly or the patterns of a carpet that are in symmetry and extension of each other, the shawls and stone veins are paired next to each other. Mainly, slab stones that have bookmatch and formmatch capabilities are processed in factories that are equipped with quality and up-to-date devices.

Uses and applications of Black Ocean slab stone

Today, the use of black stones in the interior design of buildings is much more than in the past. With its beautiful white lines, Black & White marble slabs are used in many different cases such as cabinets, elevators, the space behind the TV, lobby, etc. The quality and unique beauty of Black & White marble compared to domestic and foreign competitors has caused this stone to be used in many residential, office, commercial and luxury projects. In new methods of building interior design, it is common to use large stone sheets or slabs instead of smaller sizes. The use of black & white stone slabs and large sizes of 100 x 100 and more gives a unique beauty and uniformity to the space and makes the design more attractive. Other uses of Black & White marble slabs include:

- The interior of the building

- Paving the floor of the hall and reception

- the walls

- Stairs and under stairs

- Staircase and wall

- The walls and around the fireplace

- The edge of the elevator

- The space behind the TV (TV Wall)

- Hotels, arcades and luxury business complexes

- Lobby and building entrance

- counter and counter

- Cabinets and space inside the kitchen

- Vanities and stone art volumes

- Luxury bathrooms

- Master and luxury bathrooms

Currently, Black & White stone is produced in the form of slabs and tiles. Considering the increase in the price of raw copper and other production costs, slab processing is cost-effective. Because it has less waste and using advanced devices, sub, epoxy, UV, etc. operations are performed on it. If the polishers are of good quality and the processing and subbing operations are carried out correctly, the polished and shiny surface of the Black & White marble slab will be more attractive.